Shanghai Crane Valve Co., Ltd. (abbreviated as: Mei Crane or CRANC or SHCRANE) has been focusing on technology research and development, production, sales and professional services of high-end valves for industrial process installations in petrochemical and coal chemical industries for many years. By absorbing and comparing the technical advantages and process characteristics of international high-end brands, local innovation and formation of its own intellectual property rights, it is a professional integrator of valve technology services and manufacturing under severe conditions. Crane Valve is headquartered in Colorado Industrial Valve Manufacturer, USA. It is a manufacturer of various industrial engineering technology products. Provide a complete set of industrial valve solutions for energy, chemical, electronic environmental protection, food and other fields. |

Crane products cover most of the valves involved in automated process control: ball valves, butterfly valves, regulating valves, gate valves, globe valves, check valves, filters, and related electric and pneumatic control mechanisms. The production technology and strict quality control system ensure the reliability of the products and can adapt to relevant international standards. The raw material suppliers of Crane valve products have passed the supplier evaluation system 100% strictly and obtained the raw material quality certification. All Crane valve products use nitrogen or helium for product testing before leaving the factory. At the same time, Crane can also carry out tests under more demanding conditions according to customer requirements.

Valve products mainly include: gate valves, butterfly valves, globe valves, and check valves. Valve materials mainly include: cast iron, ductile iron, cast steel, stainless steel, copper alloy, etc. The valve adopts standards: ANSI, DIN, JIS, etc. The products range from ¼"~48"; the pressure rating is 125~800LB. The company vigorously develops technological innovation, continuously develops new products, and expands service areas. To provide all domestic and foreign users with products and services that meet the contract requirements is our promise to you. Crane has a strong after-sales service team. Technical service engineers are located all over the country, and they have German-approved qualifications, and have more than 5 years of service experience, and have the technical level synchronized with the international. Crane extends the spare parts reserve to the users. There are more than 20,000 spare parts stored in maintenance centers in industrial cities in North China, East China, South China and other industrial cities. Professional personnel, complete equipment and sufficient space can meet the limit. User needs. |

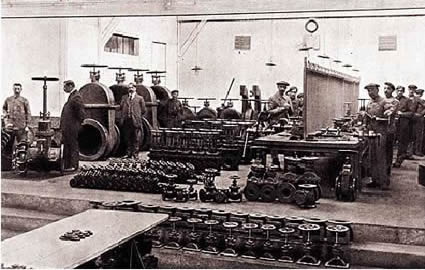

Shanghai Crane Valve Co., Ltd. has a production and operation site of 60,000 square meters, 220 employees, including 36 engineering and technical teams, and 160 sets of various key processing and inspection equipment, which meet the requirements of manufacturing licenses.

At present, the company's production, service, and sales activities are normal and orderly, the management team is stable, and the system is operating normally.

CRANC Product Range:

Pressure rating & specifications: Class150~2500; NPS1/2~60;

Temperature range: -196℃~+950℃

Product Type:

1. Control valves (pneumatic actuators, single-seat control valves, double-seat control valves, sleeve control valves, eccentric rotary control valves, control ball valves, control butterfly valves, control gate valves, etc.)

2. Conventional valves (gate valve, globe valve, check valve, ball valve, plug valve, butterfly valve, throttle valve, etc.)

3. Special valves (high pressure hydrogenation valve, forced sealing valve, wear-resistant ball valve, anti-coking ball valve, ultra-low temperature valve, special material valve, material valve, parallel double gate valve, special lock valve for coal chemical industry, lock bucket valve, Coal slurry shut-off valve, oxygen/nitrogen shut-off valve, black water flash control valve, hydraulic angle valve, etc.)

CRANC has a lot of good application performance in petrochemical process equipment, the core competitiveness of its products is obvious, the quality is reliable, the price is reasonable, and the service system is perfect. Our common vision is to achieve safe, stable, long-term, full-load, and high-quality operation of petrochemical plants. May CRANC be your partner.